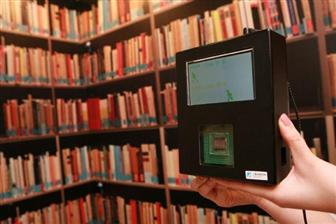

Taiwan's Industrial Technology Research Institute (ITRI) has been investigating resistive RAM (RRAM) – seen as a potential candidate to replace conventional flash memory – and development of the next-generation memory chip technology is bearing fruit.

As existing NAND flash technologies adopt the conventional floating-gate structure, further advances in shrinking process geometries will be difficult to achieve at or below the 20nm manufacturing process node. Therefore, a number of semiconductor companies have been actively looking for replacements for NAND.

RRAM is among the potential successors to NAND flash, said Frank Chen, general director of nanotechnology research center at ITRI. RRAM is a non-volatile memory able to program large amounts of data at high speeds with low power consumption, Chen indicated.

ITRI's in-house developed RRAM has been successfully incorporated in volume production, using 8-inch, 30nm processes at 2-3 local memory foundries, Chen noted. It expects to commercialize the solution as soon as possible, initially utilizing 20nm-class nodes at 12-inch foundries, Chen said.

However, issues such as technology transfer, 12-inch production yields, available production equipment and companies' willingness to spend more on new tools could interrupt future development and deployment, Chen pointed out.

Still, ITRI is looking to provide Taiwan's memory chipmakers with its know-how and patents, and expects to utilize their advantages in 12-inch wafer capacity, according to Chen.

|